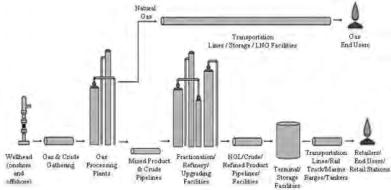

Once natural gas is produced from wells, producers then seek to deliver the natural gas and its components

to end-use markets. The following diagram illustrates the natural gas gathering, processing, fractionation,

storage and transportation process, which ultimately results in natural gas and its components being delivered to

end-users.

Natural Gas Gathering

The natural gas gathering process begins with the drilling of wells into gas-bearing rock formations. Once

the well is completed, the well is connected to a gathering system. Onshore gathering systems generally consist

of a network of small diameter pipelines that collect natural gas from points near producing wells and transport

it to larger pipelines for further transmission.

Natural Gas Compression

Gathering systems are generally operated at design pressures that will maximize the total throughput from

all connected wells. Since wells produce at progressively lower field pressures as they deplete, it becomes

increasingly difficult to deliver the remaining lower pressure production from the well against the prevailing

gathering system pressures. Natural gas compression is a mechanical process in which a volume of wellhead

gas is compressed to a desired higher pressure, allowing gas to flow into a higher pressure downstream pipeline

to be brought to market. Field compression is typically used to lower the pressure of a gathering system to

operate at a lower pressure or provide sufficient pressure to deliver gas into a higher pressure downstream

pipeline. If field compression is not installed, then the remaining natural gas in the ground will not be produced

because it cannot overcome the higher gathering system pressure. In contrast, if field compression is installed,

then a well can continue delivering production that otherwise would not be produced.

Natural Gas Processing

The principal component of natural gas is methane, but most natural gas produced at the wellhead also

contains varying amounts of NGLs including ethane, propane, normal butane, isobutane and natural gasoline.

NGLs have economic value and are utilized as a feedstock in the petrochemical and oil refining industries or

directly as heating, engine or industrial fuels. Long-haul natural gas pipelines have residue natural gas

specifications as to the maximum NGL content of the gas to be shipped. In order to meet quality standards for

long-haul pipeline transportation, natural gas collected at the wellhead through a gathering system may need to

be processed to separate hydrocarbon liquids from the natural gas that can have higher values as NGLs. NGLs

are typically recovered by cooling the natural gas until the NGLs become separated through condensation.

Cryogenic recovery methods are processes where this is accomplished at temperatures lower than minus 150°F.

These methods provide higher NGL recovery yields.

In addition to NGLs, natural gas collected at the wellhead through a gathering system may also contain

impurities, such as water, sulfur compounds, nitrogen or helium, which must also be removed to meet the

6